Our Welded AD proTex Woven Sacks

- Economical

- Better Printability

- Maximum Protection

- Zero Wastage

- Pilfer Proof

- Seepage Proof

- Easy Palatability

- Perfect Brick Shape

- No Additional Packing Cost

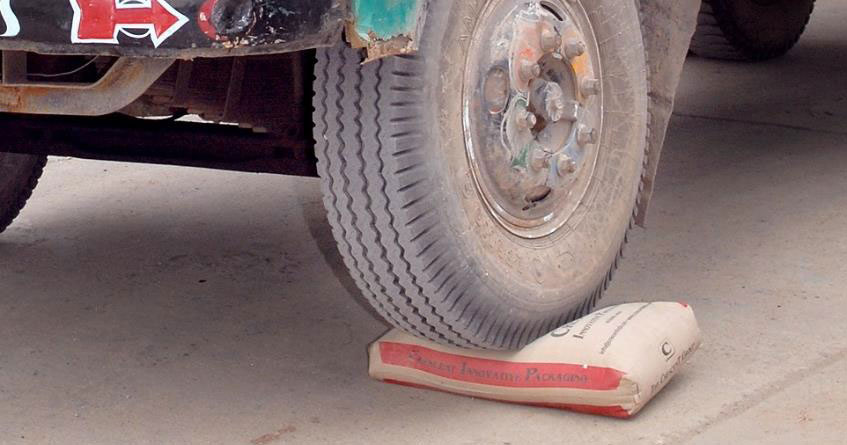

- Burst Proof

- Can easily be branded

Next Generation Packaging

- PP Block Bottom Wielded AD proTex sack are produced by using hot air wielding to seal the joints on the laminated woven fabrics.

- Production of bag involves no usage of glue, threads, stitching, reducing the cut, and eliminating holes.

- The printing is done after the lamination so the print results achievable on the sack are very attractive.

- The sack is suitable for modern fast rotopackers, and is suitable for both manual and automatic placement of the filling spout.

Environment Friendly

- Non-toxic – Not Harmful for soil and water when in contact during use or when dumped after use

- Negligible Sack Burstage

- No Spillage

Strength Tests

Our routine drop test system implemented is carried out as to check burstage:

- 3 times on the flat surface from a 5 – 6 feet height.

- 3 time on other surface from 5 – 6 feet height.

- 1 time horizontally on one side from a four feet height.

- 1 time vertically (upright ) from a 2- 3 feet height.